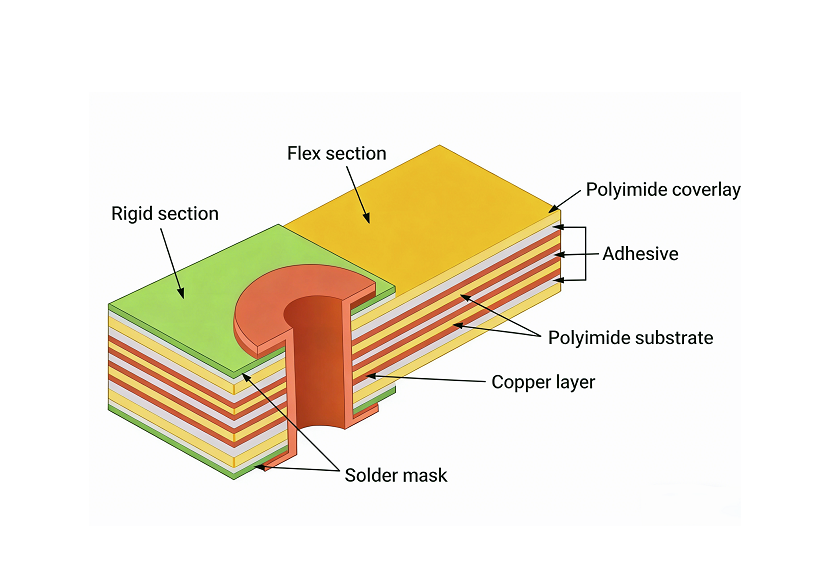

Flexible PCB Manufacturing Material selection is a critical step in determining its application suitability. Common material systems mainly include substrates, cover films, adhesives, and shielding materials. As the circuit carrier, polyimide (PI) is the mainstream substrate choice, with a temperature resistance range of -269℃ to 400℃, excellent chemical resistance and mechanical flexibility, which is suitable for most industrial and consumer electronics scenarios. The selection of materials for flexible PCB manufacturing requires multi-dimensional evaluation based on application scenarios.

1.What Materials Are Commonly Used for Manufacturing Flexible PCBs?

Common materials for flexible PCBs include core substrates (high-temperature resistant PI for high-end applications, PET/PEN for mid-to-low-end), conductive materials (ED copper for general use, RA copper for bend-resistant requirements), protective materials (cover films, solder masks, stiffeners), adhesives (adhesive-backed/adhesiveless for different needs), and surface finishes (immersion gold, tin plating, OSP). In foreign trade communications, recommendations can be made based on the customer’s product scenarios (high-end/mid-to-low-end) and temperature/bending requirements. Core English keywords: Flexible PI/PET Substrate, ED/RA Copper Foil, Immersion Gold, Adhesiveless.

2.How to Select Suitable Materials for Flex PCB Manufacturing?

1)Choose adhesiveless FCCL for fine-pitch designs

2)Select rolled-annealed copper foil for dynamic applications

3)Pick a polyimide dielectric material for thermal stability

4)Use acrylic adhesives for excellent adhesion and flexibility

5)Choose dry film polyimide coverlay for superior heat resistance

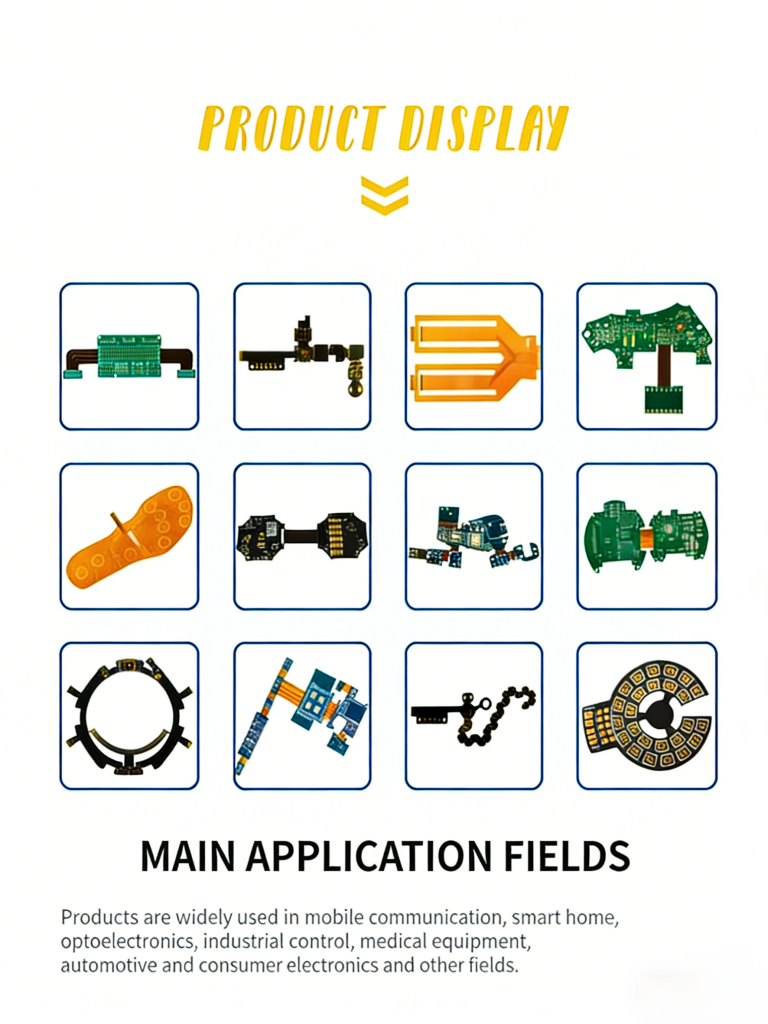

3.How to Match Flex PCB Materials to Different Application Scenarios?

The core of material matching for flexible PCBs is to align with the key performance requirements of different application scenarios (such as temperature, bending frequency, reliability, cost, etc.). Key materials (substrate, conductor, cover film, adhesive) need to be selected targeting scenario-specific pain points. Specific matching schemes are as follows:

1)Consumer Electronics Scenarios: Core requirements include thinness, light weight, high bendability, and cost control. Select PET/thin PI as the substrate and rolled annealed copper foil as the conductor, suitable for portable smart devices.

2)Automotive Electronics Scenarios: Requirements include high temperature resistance and vibration resistance. Select high-performance PI/modified PI as the substrate and electrolytic/rolled annealed copper foil as the conductor, suitable for high-temperature and vibrating automotive environments.

3)Medical Device Scenarios: Core requirements are biocompatibility and sterilization resistance. Select medical-grade PI/PTFE as the substrate and gold-plated conductors, suitable for medical equipment.

4)Industrial Control Scenarios: Requirements include wide temperature adaptation and electromagnetic interference (EMI) resistance. Select standard PI/glass fiber-reinforced PI as the substrate and tin-plated copper foil as the conductor, suitable for complex industrial environments.

5)Aerospace Scenarios: Requirements include resistance to extreme environments. Select high-end PI/PEEK as the substrate and oxygen-free/gold-plated copper foil as the conductor, which must comply with strict industry certifications.

Matching Principles: Clarify scenario-specific pain points, balance cost and performance, align with assembly processes, and meet industry certifications to ensure materials fully meet end-user requirements.

Welcome to contact Sayfu Expert today

24 hours a day,7 days a week.

Email :[email protected] | Call us:+86 133 1296 7631