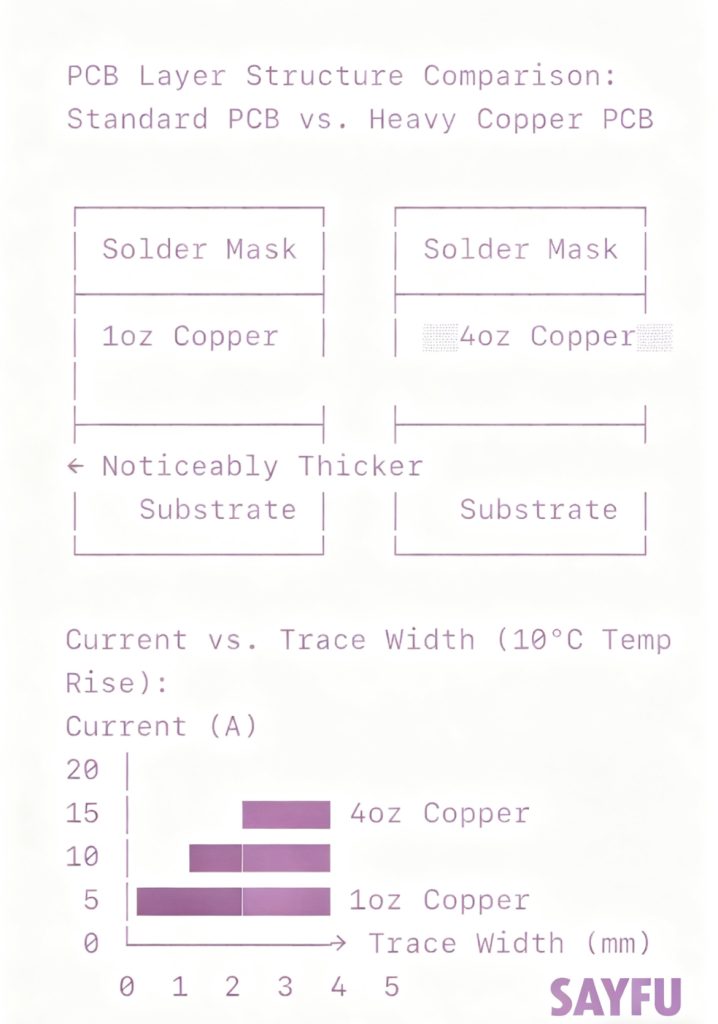

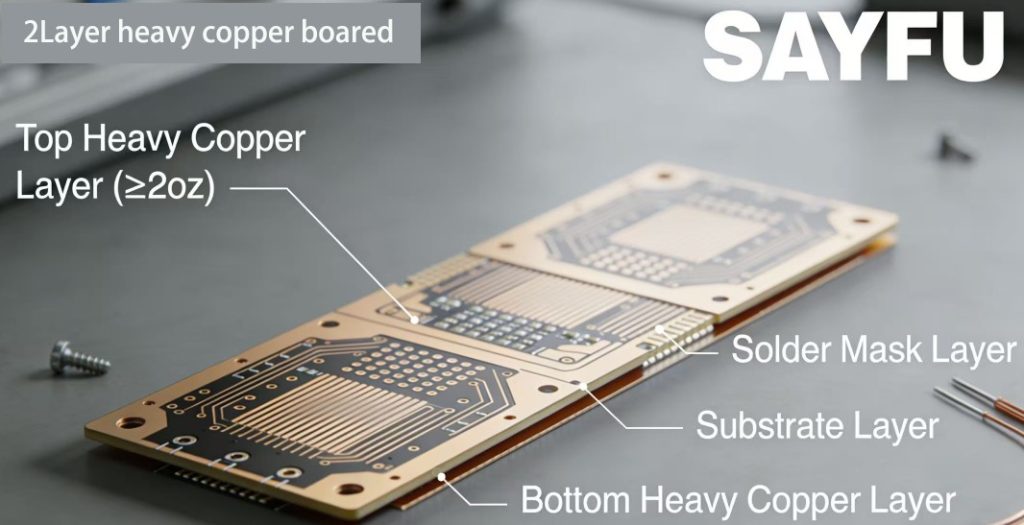

Multilayer heavy copper PCB represents a specialized and critical segment in printed circuit board technology, combining the benefits of multilayer construction with exceptional current-carrying capacity. These advanced circuit boards feature copper thicknesses typically exceeding 3 oz per square foot, compared to the standard 1-2 oz found in conventional PCBs. The growing demand for high-power applications across various industries has positioned multilayer heavy copper PCB as an essential solution for challenging electronic applications. Guangdong Sayfu Multilayer Circuits Co.,Ltd has emerged as a leading manufacturer in this specialized field, bringing decades of expertise and innovative manufacturing approaches to this demanding technology sector.

Understanding Multilayer Heavy Copper PCB Technology

The fundamental characteristic of multilayer heavy copper PCB lies in its specialized construction methodology. Manufacturers create these boards using multiple conductive layers separated by dielectric materials, with each layer containing substantial copper weights. The production process requires specialized equipment and techniques to handle the thick copper foils effectively. SAYFU employs advanced plating and etching processes that allow for different copper weights on various layers within the same board. This capability enables designers to integrate both power and control circuits within a single multilayer heavy copper PCB, optimizing space and performance while reducing system complexity.

1.Key Advantages and Design Benefits.

Multilayer heavy copper PCB offers numerous significant advantages that make it indispensable for high-power applications. The most prominent benefit is its exceptional current-carrying capacity, which allows it to handle high power levels without overheating. Additionally, these boards provide superior thermal management by efficiently dissipating heat away from critical components. The robust construction also enhances mechanical strength at connector sites and through-holes, significantly improving reliability. Furthermore, multilayer heavy copper PCB enables more compact designs by integrating multiple functions that would otherwise require separate boards. This integration reduces overall system size and weight while improving performance characteristics.

2.Manufacturing Challenges and Solutions

Producing reliable multilayer heavy copper PCB presents unique manufacturing challenges that require specialized expertise. The etching process demands precise control to maintain proper trace geometry and prevent undercutting. Similarly, the plating process must ensure uniform copper distribution across all layers and through vias. SAYFU addresses these challenges through advanced manufacturing techniques and rigorous quality control measures. Their approach includes specialized etching chemistry, controlled plating parameters, and innovative lamination processes. These methods ensure consistent results in thick copper PCB production, maintaining electrical integrity while achieving the desired mechanical properties.

3.Applications Across Industries

The unique properties of multilayer heavy copper PCB make it suitable for numerous demanding applications across multiple industries. In the power electronics sector, these boards form the backbone of power converters, inverters, and motor controllers. The automotive industry, particularly electric and hybrid vehicles, relies on them for power distribution systems and battery management. Industrial applications include welding equipment, power supplies, and industrial drive systems. Additionally, the renewable energy sector utilizes thick copper PCB in solar power inverters and wind turbine control systems. SAYFU Company has successfully delivered solutions for all these applications, demonstrating the versatility and reliability of their multilayer heavy copper PCB products.

How to choose thickness for multilayer heavy copper board

The selection is not one-size-fits-all; it is a strategic decision based on electrical and thermal requirements.

- Standard Heavy Copper (2 oz to 6 oz): This range is the most common. Boards with 4 oz to 6 oz copper are frequently used in automotive power systems, industrial controls, and welding equipment. They provide an excellent balance of increased current capacity and manufacturability.

- Extreme Heavy Copper (6 oz to 12 oz+): For the most demanding applications, such as military power supplies, deep-hole drilling equipment, or solar panel inverters, extreme heavy copper is the answer. These boards can handle immense currents and function as a structural part of the assembly.

SAYFU’s Expertise and Capabilities

SAYFU has established itself as an industry leader in multilayer heavy copper PCB manufacturing through continuous innovation and quality focus. Our state-of-the-art manufacturing facility houses specialized equipment specifically configured for heavy copper applications. our engineering team possesses deep expertise in designing and fabricating boards with copper weights ranging from 4 to 12 ounces per square foot. SAYFU maintains comprehensive quality certifications and implements strict process controls throughout manufacturing. Our technical support team works closely with clients from design conception through final production, ensuring optimal multilayer heavy copper PCB performance in each application

The copper thickness process parameters of Sayfu, along with the corresponding line width and spacing capabilities

| Items | Samples | Mass production | |

| Width/Space | Internal Layer | 1/2OZ:3/3mil | 1/2OZ: 3/3mil |

| 1OZ: 3/4mil | 1OZ: 3/4mil | ||

| 2OZ: 4/5mil | 2OZ: 4/5.5mil | ||

| 3OZ: 5/8mil | 3OZ: 5/8mil | ||

| 4OZ: 6/11mil | 4OZ: 6/11mil | ||

| 5OZ: 7/13.5mil | 5OZ: 7/14mil | ||

| 6OZ: 8/15mil | 6OZ: 8/16mil | ||

| 7OZ: 9/18mil | 7OZ: 9/19mil | ||

| 8OZ: 10/21mil | 8OZ: 10/22mil | ||

| 9OZ: 11/24mil | 9OZ: 11/25mil | ||

| 10OZ: 12/27mil | 10OZ: 12/28mil | ||

| 11OZ: 15/30mil | 11OZ: 17/33mil | ||

| 12OZ: 16/32mil | 12OZ: 18/35mil | ||

| External Layer | 1/3OZ:3/3mil | 1/3OZ:3.5/4mil | |

| 1/2OZ:3.5/3.5mil | 1/2OZ:3.9/4.5mil | ||

| 1OZ: 4.5/5mil | 1OZ: 4.8/5.5mil | ||

| 1.5OZ:4.5/6 | 1.5OZ:4.5/7 | ||

| 1.5OZ:5/7 | 1.5OZ):5/8 | ||

| 2OZ: 6/7mil | 2OZ: 6/8mil | ||

| 3OZ: 6/10mil | 3OZ: 6/12mil | ||

| 4OZ: 7.5/13mil | 4OZ: 7.5/15mil | ||

| 5OZ: 9/16mil | 5OZ: 9/18mil | ||

| 6OZ: 10/19mil | 6OZ: 10/21mil | ||

| 7OZ: 11/22mil | 7OZ: 11/25mil | ||

| 8OZ: 12/26mil | 8OZ: 12/29mil | ||

| 9OZ: 13/30mil | 9OZ: 13/33mil | ||

| 10OZ: 14/35mil | 10OZ: 14/38mil | ||

Testing and Quality Assurance

Quality assurance represents a critical aspect of multilayer heavy copper PCB manufacturing due to the demanding nature of its applications. SAYFU Company implements comprehensive testing protocols that include electrical testing, thermal cycling, and mechanical stress tests. Their quality control process begins with raw material inspection and continues through every manufacturing step. Advanced testing equipment verifies current-carrying capacity, thermal performance, and structural integrity. Additionally, the company conducts accelerated life testing to validate long-term reliability. This rigorous approach ensures that every heavy copper PCB meets the highest quality standards and performs reliably in field conditions.

Future Trends and Developments for multilayer heavy copper PCB

The future of multilayer heavy copper PCB technology continues to evolve with emerging applications and advancing material science. Industry trends point toward even higher copper weights combined with increased layer counts and density. SAYFU Company is actively developing new manufacturing techniques to support these advancing requirements. Research focuses on improved thermal management materials, advanced plating techniques, and innovative structural designs. The integration of heavy copper with other specialized technologies, such as embedded components and high-frequency materials, represents another exciting development direction. These advancements will further expand the applications and capabilities of multilayer heavy copper PCB in next-generation electronic systems.

Conclusion: The Strategic Importance of Heavy Copper Technology

Multilayer heavy copper PCB has transformed from a niche technology to a critical enabler for modern high-power electronics. Its ability to handle substantial currents while providing excellent thermal management makes it indispensable across numerous industries. SAYFU Company’s expertise and continued innovation in this field demonstrate the growing importance of specialized PCB technologies. As power densities continue to increase and electronic systems become more complex, the role of heavy copper PCB will become even more crucial. Companies that master this technology, like SAYFU, are well-positioned to support the evolving needs of the electronics industry with reliable, high-performance solutions.