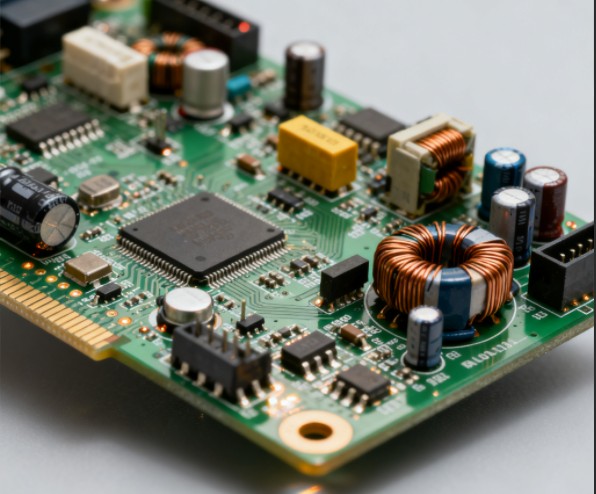

At Sayfu Company, we offer custom PCB Assembly solutions that meet the specific requirements of your products. Whether you need a special layout, unique materials, or specific performance features, our custom PCB Assembly services can ensure precision, reliability, and top-quality results. We have advanced production equipment in China, and our custom PCB Assembly capabilities, combined with the latest equipment, experienced engineers, and strict quality control, can produce circuit boards that meet the most stringent industry standards. From prototypes to mass production, we provide cost-effective, tailor-made printed circuit board solutions for industries such as medical, automotive, and consumer electronics. Partner with Sayfu Company to turn your customized printed circuit board designs into reality with speed and accuracy.

What is Custom PCB Assembly?

Custom PCB Assembly refers to the manufacturing of circuit boards based on the specific requirements of customers. This involves converting the circuit design into the actual layout of the printed circuit board, selecting suitable materials and installing components on the circuit board. Custom PCB Assembly should have an efficient strategy that combines design and manufacturing aspects. Due to its specific applications in various industries (such as medical, automotive and aerospace), the demand for customized printed circuit boards is constantly increasing. In a world where electronic products and gadgets are constantly emerging, custom PCB Assembly services have become particularly common among printed circuit board suppliers. In this regard, custom PCB Assembly in China is also quite popular in the global market.

Why choose Sayfu to meet your custom PCB assembly requirements?

Sayfu Company has fully implemented a strict enterprise management system, covering all aspects such as production, sales and after-sales service. It has achieved an operation mode that is institutionalized, proceduralized, standardized and systematized, and strictly follows the international ISO9001 quality system standards to ensure the rigor of the enterprise processes.

24 years of experience: Sayfu has been providing PCB and PCBA services since 2001. Therefore, we have an experienced sales and engineering team, as well as highly skilled workers who are very familiar with printed circuit boards.

Competitive Pricing: Reasonable and competitive pricing does not mean that we will compromise on product quality. On the contrary, we are doing our utmost to enhance production efficiency and output rate in order to reduce costs and offer products with good value for money.

One-stop service: Sayfu can meet all your requirements for custom circuit boards, including PCB design, PCB fabrication, PCB assembly, and full turnkey box build assembly.

Outstanding customer service: “Serving every customer with utmost dedication” is our motto. All the employees of Sayfu are striving to achieve this goal. Our sales team is always prompt in responding, handling inquiries, orders, issues, technical problems, and complaints in a timely manner. Meanwhile, if you don’t receive a satisfactory response from any representative, you can easily contact our CEO.

Since our establishment in 2001, we have been dedicated to the printing and assembly of custom printed circuit boards. Currently, we provide services to over 1,000 customers worldwide, covering various industries. If you have any requirements related to printed circuit board assembly, please feel free to contact us at any time. Please visit https://sayfu-multilayer.com/capabilities/smt-capacity/ to view our service capabilities.

What are the Different Types of PCBs?

Before delving into the assembly process of custom printed circuit boards, it is important to understand the different types of PCB. These circuit boards are also commonly referred to as “bare PCB”, and their classification is as follows:

Single-sided printed circuit board: The circuit patterns are printed only on one side of the circuit board. This is the simplest type, with the least complex manufacturing process and the lowest cost.

Double-sided printed circuit board: Both sides have circuit patterns. Its component density is higher than that of single-sided printed circuit board.

Multilayer Printed Circuit Board: With the continuous increase in density and complexity in printed circuit board design, multilayer printed circuit boards have been developed. These boards contain prepreg material in the middle.

Rigid printed circuit board: Currently, the majority of printed circuit boards are still rigid boards, which means they are made of hard or rigid insulating woven glass materials.

Flexible Printed Circuit Board: This is a thin and flexible substrate with excellent heat dissipation and electrical properties. It is made of high-strength polymer materials, which are commonly used in areas such as mobile phones, disk drives, and cameras.

Rigid-flex printed circuit board: Rigid-flex printed circuit board is a composite board formed by combining a rigid board and a flexible board. Rigid-flex printed circuit boards can be single-sided, double-sided, or multi-layered.

Benefits of Custom PCB Assembly

Flexibility in design and functionality: Establish flexible partnerships with customized printed circuit board assembly suppliers to meet the needs and requirements of customers. During the preparation of the circuit board, customers can choose the size and the type of components used, allowing for an unlimited range of options in design. The flexibility of the customized printed circuit board assembly service is reflected in the following aspects: flexible technology, diverse and professional engineering support, and a flexible organizational structure.

Cost optimization: Cost optimization is achieved by selecting materials based on their functions and purposes.

Higher efficiency: The customization of PCBs enables an increase in efficiency, as the design and development focus on the realization of functionality and unnecessary elements on the PCB are removed.

Superior performance: In the customized printed circuit board assembly service, performance is optimized by minimizing noise and enhancing signal integrity. This is achieved through the detailed design generated by considering the component layout, size, signal routing, and other specific requirements during the design process. Due to its uniqueness, the customized printed circuit board is more likely to be brought to the market.

Competitiveness: Customized printed circuit boards have a stronger competitive edge due to their unique design and functionality.

Custom PCB Assembly Process

1:Schematic Diagram and Layout Design

Before carrying out the custom printed circuit board assembly service, a computer-aided design (CAD) file needs to be input into the system. This file clearly indicates the positions of the components and the feed lines of the custom printed circuit board. The design data will be processed through a manufacturing file type conversion program to achieve automated printed circuit board assembly.

2:Solder Paste Printing

The first step in customized printed circuit board assembly services is solder paste printing. In this step, the solder paste is applied to the printed circuit board through a template by printing. To ensure a uniform distribution of the solder paste, a scraper is pressed into the template holes and moved back and forth on the template surface. Research shows that over 50% of welding defects are caused by solder paste printing issues. Optimization and evaluation are necessary to increase the first-pass rate. Various factors can affect the performance of template printing, including the size of the template holes, the characteristics of the solder paste, and parameter settings. During solder paste printing, some defects may occur, such as short circuits, where the solder paste “bridges” to adjacent pads, resulting in an electrical short circuit.

3:Solder Paste Inspection

The quality of solder joints is of vital importance for ensuring the electrical connection between components and the printed circuit board. The volume of solder paste can be measured using an automatic optical inspection system. The solder paste inspection machine captures images of the printed circuit board and analyzes them using processing software by matching the solder paste images with known acceptable images. In all detection systems, lighting is crucial as good lighting can provide clearer images, thereby improving accuracy and efficiency. At the same time, the positioning of the lighting must be studied to ensure that all areas of the solder paste are inspected.

4:Component Placement

The component placement machine is a high-speed, automated device that can meet the demand for high production output. In this customized printed circuit board assembly process, various types, shapes and sizes of electronic components are installed on the bare printed circuit board. The machine’s mechanical arm first returns to the starting position and then moves to the clamping device. After obtaining the appropriate fixture, the mechanical arm moves to the specific feeder and takes out the component, and then places the component at the designated position on the circuit board. The sequence of the grasping and placement actions of the machine continues until the last component is placed in the correct position on the circuit board.

One possible problem during the component placement process is component misalignment caused by the fluidity of the solder paste and the uneven placement during the movement of the mechanical arm. During the subsequent reflow process, the components may still achieve automatic alignment, but such misalignment should be minimized and optimized as much as possible. Other factors that cause component misalignment include machine vibration, unstable PCB installation, and uneven solder paste distribution.

5:Solder Reflow

The circuit board with solder paste and installed components will pass through a reflow oven. During this process, it will first be preheated to evaporate the solder, reach the peak temperature to melt the solder paste and form metal compounds, thereby forming the required welding joints. In order to ensure that the components are completely attached to the surface of the printed circuit board’s pads, the temperature must exceed the melting temperature of the solder alloy. This melting process causes the metal filler to aggregate into a solder volume, and then wet the surface of the printed circuit board.

This reflow process is achieved by using a furnace equipped with a series of independently programmable heating zones. Modern reflow equipment typically employs convective heat transfer to effectively heat the entire printed circuit board assembly. The common practice for evaluating the reflow curve of a custom printed circuit board is to install external thermocouples based on engineering judgment and professional knowledge of similar products or component types. Then, the circuit board is placed in the oven, and modifications can be made after the initial settings are completed until the most ideal thermal distribution curve is obtained. The thermal curve is a time-temperature graph that determines the heating distribution between the PCB and the solder paste, ensuring the formation of good solder joints. There are four main stages in the reflow welding process:

Preheating: Gradually increase the temperature to ensure the circuit board reaches the preset temperature.

Soaking treatment: Allow the soldering agent to fully function, to prevent metal oxidation at the solder pads on the printed circuit board surface.

Reflow: The solder particles melt and turn into a liquid.

Cooling process: Finally, solder joints were formed between the components and the pads on the printed circuit board.

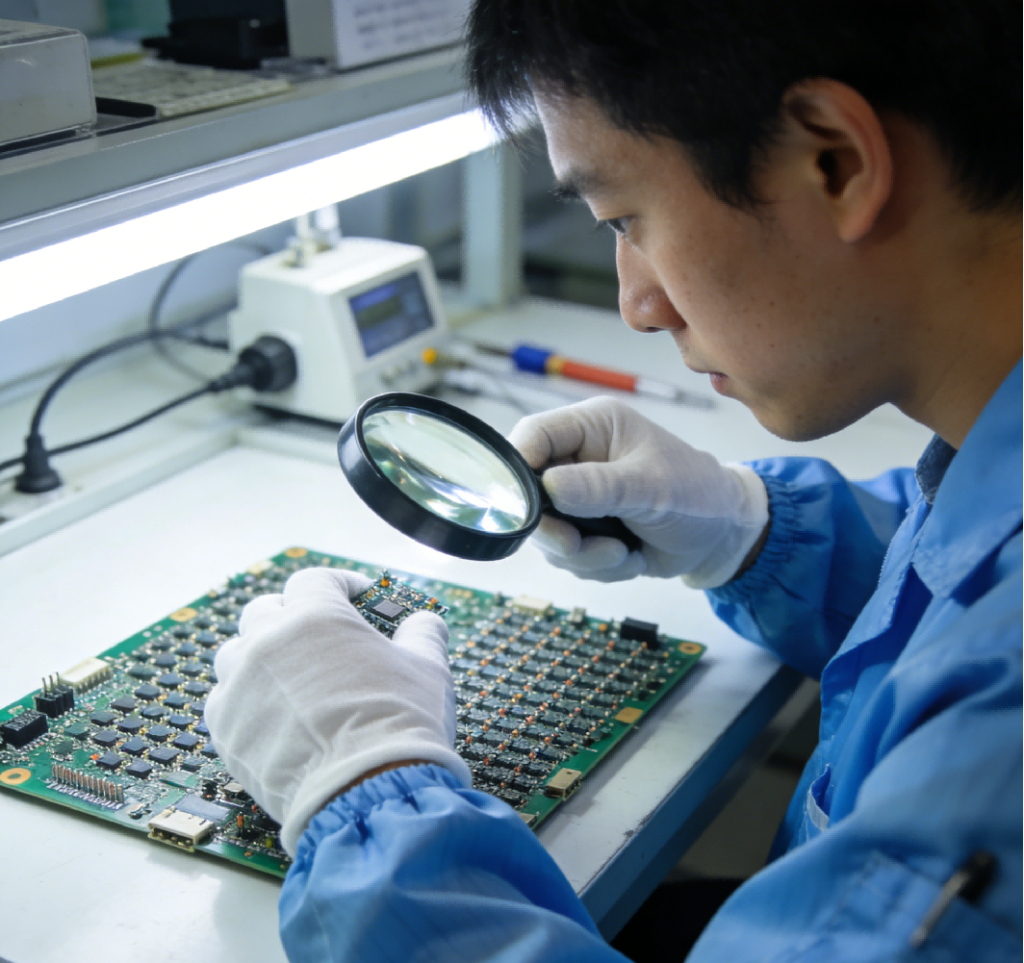

6:AOI Inspection

In the customized printed circuit board assembly service, quality is of utmost importance. During the customized printed circuit board assembly process, any defects on the circuit board should be detected as early and accurately as possible to prevent failures in actual applications. Manual visual inspection has some limitations, such as high false detection rate and slow processing speed. However, the automatic optical inspection system has certain advantages, such as high efficiency, zero and operation-related defects, and high detection accuracy. AOI (Automatic Optical Inspection) scans the entire circuit board, captures images, and compares them with reference images to determine if there are any abnormalities or defects.

Things to Consider When Choosing a Custom PCB Assembly Supplier

Price Competitiveness

Cost plays a crucial role in the decision-making process of the supplier sourcing teams. A manufacturer that can provide low-cost customized PCB assembly will have an advantage among numerous potential candidates. Despite special requirements, customized PCB assembly suppliers should still be able to offer competitive price advantages, thus being selected as the provider of customized PCB assembly services. Larger quantities usually help to reduce costs. Detailed quotations will help you understand the cost of each material and the customized PCB assembly process, and provide you with suggestions for further cost reduction and negotiations with the customized PCB assembly manufacturer. The price of PCB is affected by various factors, such as the number of layers, material selection, PCB size, and design complexity. Therefore, Chinese customized PCB assembly manufacturers have a significant advantage compared to customized PCB assembly manufacturers in European countries.

Delivery Time and Logistics Considerations

PCBA suppliers that can offer quick delivery times will have an advantage in the customer selection process. Delivery time is highly dependent on the complexity of the PCBA design and the quantity required. Consideration should be given to the entire service from PCB manufacturing to Custom PCB Assembly to understand the factors related to delivery time and logistics. If the delivery date is not met, corresponding penalties must be agreed upon. There should be flexible options for faster delivery and shorter delivery periods. All these terms and conditions should be clearly stated in the quotation. Most of the time, Chinese PCBA suppliers perform well in terms of delivery time and logistics.

Quality Requirements

Professional PCBA manufacturers usually provide a checklist that requires them to respond regarding the quality and compliance status. The ISO has a set of standards for defining the requirements of a quality management system. The UL is also an independent product safety testing agency that is responsible for certifying electronic products. All components, including the smallest ones, must meet the requirements of UL to ensure compliance with safety, quality, and performance standards. Quality control measures should also be in place on the production line of PCB assembly service providers, so that defects can be detected in time and any problems can be easily resolved during the custom printed circuit board assembly process. Electrical testing of printed circuit boards is a necessary step before shipment, so only high-quality circuit boards will be delivered to customers. All these quality control measures must be reflected in documentation.

The technical capabilities of Custom PCB Assembly manufacturers

Since PCB Assembly requires highly specialized and precise equipment, a Custom PCB Assembly manufacturer should possess the corresponding resources and capabilities to provide customized services. Since circuit board designers and suppliers frequently communicate and negotiate about requirements, limitations, and risks, the preferred supplier should have professional knowledge and technical capabilities in design rules, equipment capabilities, and potential problems. If there is a misunderstanding about the requirements at the initial stage of the customized circuit board project, problems and delays may occur. On-site inspections will also greatly help with the actual and first-hand assessment of the customized PCB assembly service provider. During the inspection, the circuit board assembly line and control system can be evaluated and audited to understand whether the production site can produce high-quality circuit boards.

Low MOQ

Unlike mass-produced PCBA, the production of small-batch PCBA requires more time and effort, and its yield rate is relatively lower. Therefore, many PCBA suppliers have little interest in the customized printed circuit board assembly services for small batches. This leads to a smaller number of PCBA manufacturers capable of meeting medium and small batch production needs. Due to technical limitations and other factors, some manufacturers have minimum order quantity requirements. Therefore, it is best for customers to communicate with the manufacturers in advance to control costs and solve related problems. If you plan to cut expenses, it is recommended to contact the custom printed circuit board assembly manufacturers in China.

The mass production of PCBs is becoming increasingly popular due to its numerous advantages. Custom design for specific applications may be the best option, especially when standard printed circuit boards cannot meet the required performance. During the initial stage, design development and prototype production should be carried out to determine whether the customized printed circuit board can meet the required performance. If the design and testing are not done properly, then the entire design, manufacturing and testing process will inevitably need to be repeated, which means the project will require additional costs and time.

Therefore, finding the right custom PCB assembly service provider is crucial for achieving efficient communication and understanding of requirements throughout the entire product lifecycle. If you are looking for any potential custom PCB assembly suppliers, look no further than Sayfu Company, which is a custom PCB assembly provider based in China.